A single line from an old construction manual stopped me cold: When entering the mountain to fell timber, one must not disturb the ridge. Not “don’t cut the wrong tree.” Not “use the sharpest axe.” Don’t disturb the ridge. The instruction assumes you already know your trade. What it insists on is something harder—restraint before action.

That line belongs to the Lu Ban Jing, a building manual first compiled during the Ming dynasty’s Yongle period, roughly the early 1400s. Lu Ban himself was a semi-mythical figure from the Spring and Autumn period, around the 5th century BC—a carpenter so skilled that his name became shorthand for craftsmanship itself. Temples were built in his honor. His title was conferred by imperial decree. But the book bearing his name is less about celebrating genius and more about codifying discipline. It reads like a foreman’s notebook crossed with a farmer’s almanac: when to raise the ridge beam, which direction to face the scaffolding, how to select timber that won’t split under load.

What struck me wasn’t the technical detail—though there’s plenty of it. It was the underlying philosophy. Every instruction in this manual assumes that building well means thinking before cutting, observing before acting, and respecting the material before shaping it. That’s not ancient mysticism. That’s engineering wisdom dressed in older clothes.

And it maps, with surprising precision, onto the experience of working with interlocking wooden puzzles today.

The Foreman’s First Rule: Preparation Is Not Optional

The manual opens with a section on construction protocol that most modern builders would find bewildering. Before a single piece of timber is selected, there are considerations about timing, orientation, and sequence. Which day to begin scaffolding. Which direction the work should proceed. Whether the household has properly prepared.

None of this is superstition for its own sake. Stripped of its cosmological language, the manual is making a practical argument: rushed beginnings produce flawed structures. A carpenter who raises scaffolding on the wrong day isn’t cursed—he’s underprepared. He hasn’t checked his materials, hasn’t read the site, hasn’t consulted the owner about what the building needs to accomplish.

This principle—preparation before execution—runs through every section. The text specifies that when constructing a new dwelling, the carpenter must first understand the existing structure before modifying it. Demolishing old walls requires different timing than raising new ones. Roof beams have their own protocol. Even the order in which pillars are erected follows a logic rooted in load distribution, not ceremony.

For anyone who has attempted a six-piece burr puzzle, this resonates immediately. The six notched sticks look interchangeable. They’re not. Each has a specific position, a specific orientation, and a specific order of assembly. Forcing pieces together produces a loose, unstable structure that collapses under its own weight. Understanding the sequence first—observing the notch patterns, identifying the key piece—produces a lock so tight you’d swear it was carved from a single block.

The old manual and the modern puzzle share the same conviction: the work begins before the work begins.

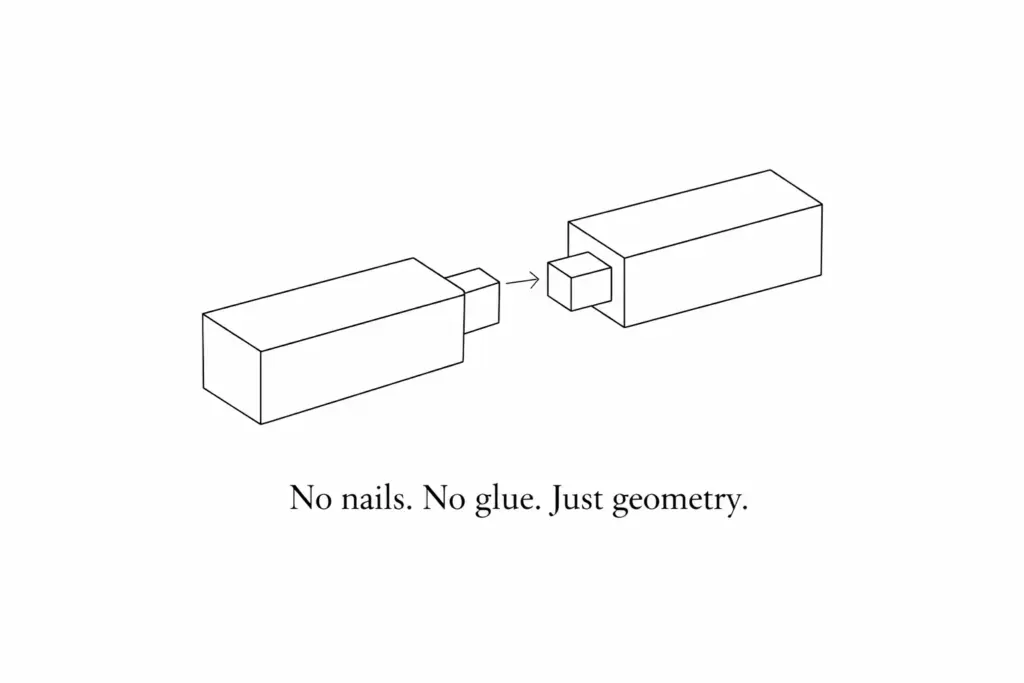

Mortise-and-Tenon: The Joint That Changed Everything

The construction methods described in the manual revolve around one structural principle: mortise-and-tenon joinery. A protruding piece (the tenon) fits into a carved cavity (the mortise). No nails. No adhesive. Just wood shaped to grip wood, held together by geometry and friction.

This isn’t a primitive technique. It’s an elegant one. Mortise-and-tenon joints allow for expansion and contraction as wood responds to humidity and temperature changes. Nailed joints crack under the same stress. Glued joints fail when adhesive degrades. A well-cut mortise-and-tenon joint actually gets tighter with age, the wood fibers compressing into each other over decades.

The manual describes how scaffolding frames (架马, literally “frame-horses”) should be assembled using these joints, with specific instructions for fire-safety configurations when working near existing structures. Even decorative and symbolic elements relied on the same structural logic—the octagonal forms found in architectural detailing, for instance, carried philosophical meaning while distributing load evenly, a principle echoed in the Bagua Lock Puzzle, whose zinc-alloy octagonal frame requires precisely calibrated rotation to unlock. The carpenter must know not only how to build but how to build safely around what already exists—a concern that feels remarkably contemporary.

This same joinery lives inside every Luban lock puzzle produced today. The Barrel Luban Lock is a direct descendant of these construction principles. Its barrel-shaped assembly uses interlocking wooden pieces with no fasteners—only the precision of the cuts holds it together. Disassembling it teaches you how the joint works. Reassembling it teaches you something else entirely: that the system only functions when every piece supports every other piece simultaneously. Remove one, and the structure isn’t weakened. It ceases to exist.

The manual’s authors understood this interdependence instinctively. When they wrote about pillar placement—specifying that the main pillar must be set before secondary supports, and that the white star position determines structural hierarchy—they were describing load paths. The language is cosmological. The engineering is sound.

Reading the Grain: How Old Builders Chose Their Materials

One of the manual’s most detailed passages concerns timber selection. The rules for entering the mountain to fell trees are specific and layered. Don’t fell from the ridge line. Select timber where the roots are established and the grain runs straight. Avoid trees that have grown in conflict with neighboring trunks—they carry internal stress that will split under load.

This is materials science expressed through observation rather than laboratory testing. A tree that grew fighting for light develops reaction wood—denser on one side, prone to warping. A tree from the ridgeline grew in thin soil with shallow roots; its wood is brittle. The manual doesn’t explain the cellular mechanics. It doesn’t need to. Centuries of trial and error produced the same conclusions that modern wood science confirms.

The manual also addresses timber dimensions with surprising specificity. Pillar circumference, beam thickness, and the relationship between span and depth are all discussed. The text notes that timber for pillars should be selected from trees whose trunks are straight for at least the height needed, without knots or bends in the working section. The grain must be consistent—no twisting, no reaction wood, no bark inclusions.

This attention to material quality is what separates a puzzle that feels good from one that frustrates. When you handle a well-made wooden puzzle—the kind where the interlock puzzle sphere pieces slide apart with a satisfying whisper rather than a gritty scrape—you’re feeling the result of careful wood selection. Consistent grain means consistent tolerances. Consistent tolerances mean the puzzle works every time, not just when the humidity is right.

The old builders had a phrase for this: use good wood, consult the root and grain, and stand it upright. The modern version might be: respect your materials, and they’ll cooperate.

The Scaffolding Problem: Building the Thing That Builds the Thing

A section of the manual that rarely gets discussed—because it’s unglamorous—concerns scaffolding construction. The text distinguishes between scaffolding for new construction and scaffolding for renovation. It specifies joint types for temporary structures. It addresses the problem of working near fire hazards, noting that when a new dwelling is being built adjacent to an existing one, fire-avoidance protocols must govern the scaffolding layout.

This is meta-construction: building the infrastructure that enables the real building. And it’s treated with the same rigor as the final structure. The scaffolding must be level. The joints must be secure. The frame-horses must support the weight of workers and materials without flex or wobble.

There’s a lesson buried here that applies far beyond carpentry. The manual insists that temporary structures deserve the same care as permanent ones. A sloppy scaffold doesn’t just risk a fall—it produces sloppy work at every level above it. If the platform isn’t stable, the carpenter can’t make precise cuts. If the cuts aren’t precise, the joints won’t seat. If the joints don’t seat, the building fails.

Anyone who has tried to assemble an eleven-piece Twin Star puzzle on a cluttered desk knows this principle viscerally. The workspace is the scaffold. Clear the surface, lay out the pieces in order, identify the three distinct block types before attempting assembly—and the puzzle becomes manageable. Skip this preparation, and you’re fighting chaos.

Breaking Ground: The Ritual of Beginning

The manual devotes considerable attention to the act of breaking ground—动土, literally “moving earth.” This section covers directional considerations, timing protocols, and the sequence of rituals that precede any earthwork. The text specifies which directions carry risk during particular periods and which configurations of timing produce favorable conditions for foundation work.

Stripped of its calendrical framework, the underlying principle is about commitment. Breaking ground is irreversible. Once you dig, you’ve committed to a location, an orientation, a structural plan. The elaborate preparation isn’t about appeasing cosmic forces—it’s about ensuring you’ve thought through every variable before making changes you can’t undo.

This is why the manual specifies that the master carpenter (作主, literally “the one who makes”) must verify the site personally. Not an apprentice. Not an assistant. The person responsible for the outcome must be the person who assesses the starting conditions.

In puzzle terms, this maps to a moment every solver recognizes: the instant you decide to commit to a configuration. With wooden brain teasers that use hidden latch mechanisms, there’s often a point where you’ve moved three pieces into position and the fourth will either lock the assembly or jam it. Rushing past this decision point—committing without checking—means starting over. The Divine Power Puzzle Lock, with its rotating center column and deliberately deceptive key trap, makes this principle visceral—the obvious solution is a decoy, and committing to it wastes time you could have spent observing. The manual would say: verify before you move the earth.

The Carpenter’s Calendar: Why Timing Matters

The final pages of the manual contain dense tables of auspicious dates for specific construction activities. Raising the ridge beam. Laying the roof. Plastering walls. Opening pillar mortises. Laying foundations. Masonry work. Each activity has its own calendar of favorable and unfavorable days.

The modern reader’s instinct is to dismiss this as superstition. But consider what the calendar actually accomplishes: it forces the builder to plan in sequence. You can’t plaster before the walls are up. You can’t raise the ridge beam before the pillars are set. The calendar imposes a project timeline that respects dependencies. It’s a Gantt chart written in cosmological language.

More practically, the timing considerations may reflect real-world material constraints. Plastering in high humidity causes adhesion failure. Raising heavy beams during certain wind conditions is dangerous. Setting foundations during the rainy season undermines compaction. The “auspicious day” may simply be the day when conditions are right—a fact obscured by centuries of accumulated ritual language.

This sequential discipline—do things in the right order, at the right time, under the right conditions—is the beating heart of the manual. And it’s the beating heart of every well-designed puzzle. The Luban Sphere disassembly sequence has exactly one correct starting piece. Find it, and the remaining five pieces separate in clean succession. Miss it, and you’re wrestling with a wooden ball that has no intention of cooperating.

What the Master Builder Actually Built: A System, Not a Structure

Reading the manual from beginning to end reveals something unexpected. Lu Ban—or whoever compiled these instructions in his name—wasn’t primarily teaching people how to build houses. He was teaching them how to think about building. The difference matters.

A set of instructions for building a specific house would be useless for the next project. A system for approaching any building project—assess the site, understand the existing conditions, select materials with care, prepare thoroughly, proceed in sequence, verify before committing—works forever. The manual is less a recipe and more a methodology.

This is why the text survived six centuries. Not because people still build the way Ming-dynasty carpenters did, but because the principles transfer. Preparation before action. Respect for materials. Sequential discipline. The courage to verify before committing. These aren’t construction techniques. They’re cognitive tools.

The Barrel Luban Lock

The Barrel Luban Lock makes this connection tangible. Named directly after the legendary carpenter, this barrel-shaped wooden puzzle uses traditional mortise-and-tenon joinery to create an assembly that holds together without nails or glue. Taking it apart is straightforward—you’re disassembling someone else’s careful work. Putting it back together demands that you understand the system: which piece supports which, what order the assembly requires, and why forcing a piece into the wrong position doesn’t just fail—it prevents every subsequent step from working.

The puzzle doesn’t come with the old manual’s cosmological framework. But it carries its engineering philosophy intact. Patience over force. Observation before action. The structure holds because every element is in the right place, not because anything is holding it there.

- Material: Premium hardwood with mortise-and-tenon joinery

- Difficulty: Intermediate—accessible for first-time puzzle buyers, rewarding for experienced solvers

- Best for: Anyone drawn to tactile problem-solving and the satisfaction of a system that clicks into place

- Skip this if: You want a quick solve. The barrel rewards careful study, not speed.

54-T Cube Puzzle

If the Barrel Luban Lock embodies the manual’s joinery principles, the 54-T Cube Puzzle embodies its sequential discipline. Fifty-four identical T-shaped beechwood blocks must be layered into a perfect 3×3×3 cube. The catch: the first two layers set the pattern for the remaining four. Get the foundation wrong and the structure won’t close. Get it right and the blocks lock together with the same self-supporting precision the manual describes for pillar-and-beam assemblies.

This is the carpenter’s calendar translated into wood blocks. Each layer depends on the one below it. The sequence is non-negotiable.

- Material: Sustainably sourced beechwood (walnut option available)

- Difficulty: Moderate—the pattern is learnable, but the first solve takes genuine patience

- Best for: Systematic thinkers, STEM learners, anyone who enjoys methodical challenges

- Skip this if: You prefer puzzles with hidden mechanisms or surprise reveals. This one rewards discipline, not discovery.

Silver Heart Lock Puzzle

Not everything in the manual is about load-bearing structures. One passage describes the symbolic function of architectural elements—how gates and doorways carry meaning beyond their structural role, how the threshold marks a transition between public and private, outer and inner. The Silver Heart Lock Puzzle operates in this symbolic space. Its heart-shaped silver-plated form is decorative, but the mechanism inside demands the same methodical approach the manual prescribes: orient correctly, apply gentle force in the right direction, and let gravity do the final work.

- Material: Silver-plated metal with internal pin mechanism

- Difficulty: Beginner-friendly once you understand the principle

- Best for: Gift-giving, especially for someone who appreciates objects that mean something beyond their function

- Skip this if: You want a long, complex solve. This one is elegant and brief.

View the Silver Heart Lock Puzzle →

The Apprentice’s Dilemma: Learning by Doing, Failing by Rushing

The manual addresses the relationship between the master carpenter and his workers with a phrase that translates roughly as: the builder-master uses name-certified craftsmen; apprentices may not issue construction tallies in their own year. In other words, until you’ve completed your training, you don’t get to authorize work.

This isn’t elitism. It’s quality control. The manual recognizes that competence isn’t granted by ambition—it’s earned through demonstrated skill. An apprentice who hasn’t internalized the system will make errors that compound through every subsequent phase of construction. A pillar set two degrees off plumb produces a roof beam that doesn’t seat, which produces a ridge line that sags, which produces a structure that fails within a decade.

The same compounding error shows up in puzzle-solving. When you’re working through the collector-grade brain teasers that combine mechanical artistry with genuine difficulty, skipping the observation phase doesn’t save time—it costs it. Every wrong assumption about a mechanism’s function adds another five minutes of backtracking. The experienced solver appears faster not because their hands move quicker, but because they’ve eliminated wrong paths before picking up the puzzle.

The manual would recognize this instantly. Mastery isn’t about speed. It’s about the elimination of waste.

Fire, Water, and the Things You Can’t Control

One of the manual’s recurring themes is hazard awareness. Entire sections address fire avoidance during construction—not just how to prevent accidental ignition, but how to design structures that resist fire spread. When building near existing dwellings, the text specifies that scaffolding layout must account for fire evacuation routes. When selecting timber storage locations, proximity to heat sources is explicitly prohibited.

Water damage receives similar attention. Foundation depth, drainage direction, and the relationship between ground level and floor height are all specified. The text notes that foundations must account for seasonal water table fluctuations—a concern that modern builders address with identical logic and different tools.

These passages remind us that the manual isn’t just about building beautiful things. It’s about building things that survive contact with reality. The most elegant joinery in the world means nothing if the building floods or burns. The master carpenter plans for failure modes, not just success conditions.

This honestly is what separates thoughtfully designed brain teasers from cheap novelties. A well-made wooden puzzle accounts for the ways it might fail—edges are rounded so repeated handling doesn’t cause splintering, tolerances are set so humidity changes don’t jam the mechanism, finishes are chosen to resist the oils from human hands. The Metal Grenade Lock Puzzle takes a different approach to durability—cast metal construction that withstands thousands of twists—but the principle is identical: build for repeated use, not just first impressions. Even topology-based puzzles like the Double G Lock, where two G-shaped metal pieces interlock through spatial reasoning rather than brute force, are engineered to survive the fumbling hands of confused first-time solvers.

What Lu Ban Would Recognize Today

Walk through a hardware store, and you’ll find nail guns, construction adhesive, engineered lumber, and laser levels. Lu Ban’s tools are gone. But his principles aren’t.

The idea that you should understand your materials before shaping them. The conviction that sequence matters—that doing things in the right order produces results that doing them in any order cannot. The insistence on preparation as the foundation of execution. The recognition that temporary structures (scaffolding, jigs, worktables) deserve the same care as permanent ones. The uncomfortable truth that mastery requires patience, and patience requires the willingness to do things slowly when everything in you wants to go fast.

These principles are portable. They work for building houses, solving puzzles, writing code, planting gardens, and raising children. They work because they describe something true about the nature of complex systems: the parts must support each other, the sequence must respect dependencies, and the whole is only as strong as the care invested in its weakest joint.

The manual’s authors understood something else, too. They devoted pages to what we might call “who should not build”—situations where the conditions aren’t right, the preparation hasn’t been done, the timing is wrong. They weren’t trying to exclude people from carpentry. They were trying to prevent the kind of damage that happens when someone with insufficient understanding attempts work that exceeds their preparation.

If you’re drawn to the idea of working with your hands, solving spatial problems, and experiencing the satisfaction of a system that locks into place through pure geometry, the tradition of wooden interlocking puzzles is one of the most accessible entry points. You don’t need a workshop. You don’t need an apprenticeship. You need a wooden puzzle, a clear desk, and the willingness to sit with confusion until it clarifies into understanding. For those who prefer metal to wood, the same philosophy lives in pieces like the Cupid’s Arrow Heart Lock, where interlocking rings require pressing, rotating, and strategic alignment—a mechanical argument that force solves nothing, but understanding solves everything.

But if you’re someone who throws things when frustrated, prefers digital entertainment, or needs immediate gratification from every activity—these puzzles will annoy you. That’s not a failing. It’s a mismatch. The manual itself would approve of this honesty: know yourself before you begin.

The Joint Holds

Six hundred years after its compilation, the Lu Ban Jing sits in a strange category. It’s too practical to be philosophy, too ritualized to be a modern engineering manual, too specific to be literature, too broad to be a building code. It survives because it occupies the space between all of these—a document that teaches thinking as much as technique.

The mortise-and-tenon joint at its center is both a construction method and a metaphor. Two pieces shaped to receive each other, holding firm without external fasteners, growing tighter with time. It’s a model for any system—structural, interpersonal, intellectual—that derives its strength from internal coherence rather than external force.

When you pick up a Luban lock puzzle and feel the pieces click into position, you’re participating in a tradition that predates the manual itself. Not a tradition of puzzles, exactly. A tradition of paying attention. Of respecting the grain. Of trusting that the system works if you work the system.

The ridge beam goes up last. The preparation comes first. And the joint holds because someone took the time to cut it right.

For readers looking to explore where structural engineering principles meet wooden puzzle design, or to examine how the same spatial reasoning that governed ancient construction now appears in metal brain teasers, the rabbit hole goes deep. The manual would approve. It was written for people who wanted to understand, not just for people who wanted to build.